Underground non-coal mining, tunnel engineering and quarrying face challenges such as high rock hardness and high safety requirements. Traditional equipment is difficult to fully meet efficiency and safety requirements. In these complex working environments, how to improve construction efficiency, reduce safety risks and control costs has become an important issue facing enterprises.

In actual operations, we found that many mining companies and engineering contractors generally face the following problems: equipment performance cannot match the difficult and complex working environment, resulting in low construction efficiency, frequent safety hazards, difficult cost control, limited project progress, and hindered business development. Traditional mining equipment often shows a situation of being unable to cope with the crushing of super-large hard rocks, unable to effectively improve work efficiency, and unable to meet the requirements of modern construction safety standards.

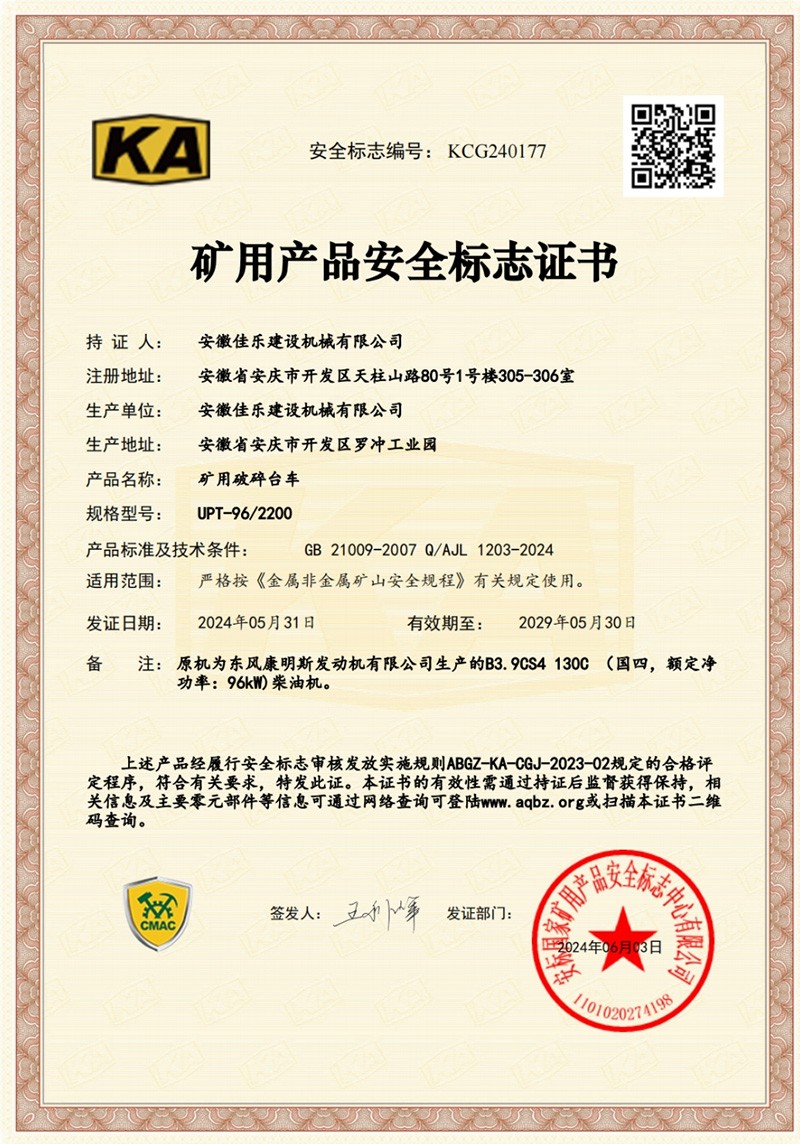

UPT-96/2200 mining crushing trolley, as the flagship product of Anhui Jarlo, provides you with a full range of solutions:

Powerful power and stable drive: The hydraulic torque converter and gearbox drive the engineering chassis, four-wheel drive, large driving torque, high bulldozing ability, and excellent climbing performance. Whether on steep slopes or narrow tunnels, it can operate stably and efficiently.

Excellent safety guarantee: The cab meets the mine safety ergonomic design and has passed the two international certifications of FOPS and ROPS anti-smash and anti-rollover at one time. Centralized control, reasonable layout, comfortable and convenient; at the same time, the cab can be raised and lowered, with strong passability, providing operators with the best working environment and safety guarantee.

Efficient and durable working performance: Equipped with a fully hydraulic telescopic and rotating mechanical arm, it has strong load-bearing capacity, stable movement, flexible operation, and no construction blind spots. The articulated special chassis design has a smaller turning radius and meets the needs of shaft and tunnel operations to the maximum extent. The breaker adopts the industry-leading Korean imported brand products, with stable performance, flexible switching, high impact energy, small recoil force, long service life, effectively reducing maintenance costs and improving equipment utilization.

Safe and reliable operation guarantee: Hydraulic wet dual brake system, driving oil brake, parking closed spring brake, ensure the safe use requirements of long ramps and low tunnels in the mine, and provide reliable operation guarantee for your construction work.

Anhui Jarlo, based on the research and development and manufacturing of underground non-coal mines and tunnel engineering equipment, has been committed to providing professional and efficient mechanized construction equipment for many years, and continuously promoting technological innovation and progress in the industry. Our products are sold all over the country and exported to many countries and regions, and are deeply trusted and praised by major mining companies and engineering construction companies.

Our mission is to help mine tunnels be constructed safely and efficiently, and to create greater value and returns for our customers. Choosing Anhui Jarlo means choosing top technical strength and a rock-solid partnership. Let us work together to create a better future and build a brilliant future!