Product Introduction

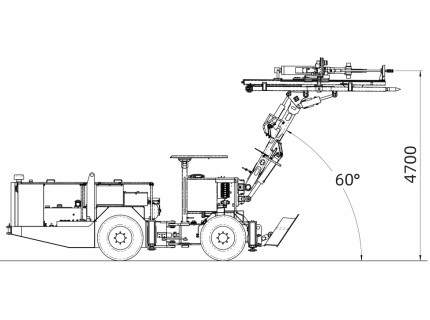

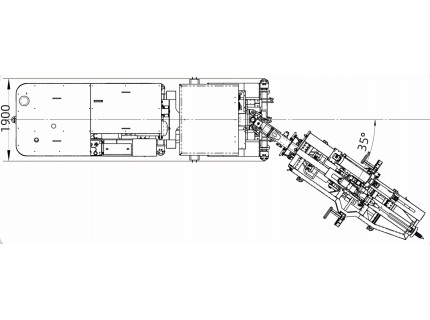

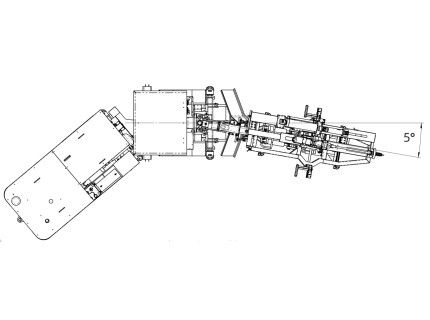

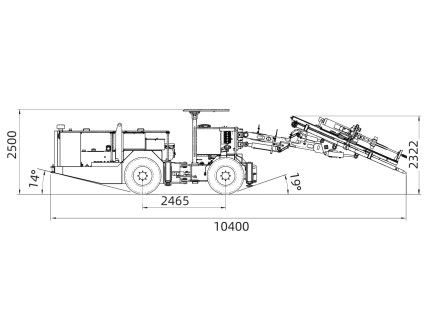

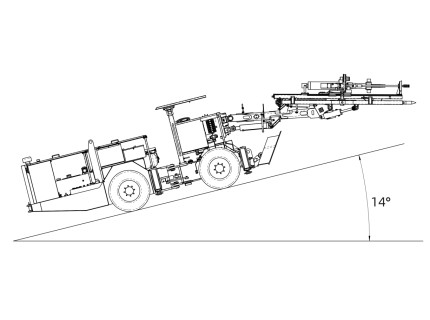

Product Pictures

Product Features

1.Full diesel power, stable performance, high torque, strong power.

2.Closed hydrostatic driving system, four-wheel drive, strong passing performance, fast transfer speed; modular design, articulated steering, flexible steering.

3.Dual-circuit wet brake system, driving oil brake, parking spring brake, meet the safety requirements of mines.

4.Adopt customized large-diameter hydraulic rock drill, high drilling efficiency and low drilling cost.

5.High-boost airborne splitter, large splitting force and good splitting effect.

6.Integrated drilling and hydraulic splitting functions in one, compact and reasonable layout, improve working efficiency.

7.Pneumatic slag removal, water mist dust suppression system, meet the requirements of damp and closed underground dust removal.

8.Remote video control system (optional), can realize drilling, splitting, switching workstations and other operations through video remote control, safe and reliable.

9.Intelligent programming controller, reduce the number of electrical components, simple wiring.