Product Introduction

Product Pictures

Product Features

1.Safe and reliable: The drill bit is directly driven by a low-speed, high-torque hydraulic motor, and the mechanical seal device effectively solves the problem of high-pressure gas and water contaminating the hydraulic motor; the drill bit motor has a long life and simple maintenance. The air and water system uses an integral connection between the motor and the cleaning machine, which has reliable performance and a long service life. The electronic pulse oil injection system allows the impactor to be effectively lubricated and has a long service life.

2.Drive mode: The machine is powered by electricity, with low operating costs, low energy consumption, and low noise. The wheels are independently driven by a travel motor, and the drilling rig has a strong driving capacity. It can turn 360° on the spot and has excellent maneuverability.

3.Drilling performance: The guide rail section adopts a V-shaped structure, with good guidance, high drilling accuracy, and a drilling deviation rate of less than 1%. High-pressure rock drilling has a fast speed, with a drilling speed of 0.2 m~0.3 m per minute.

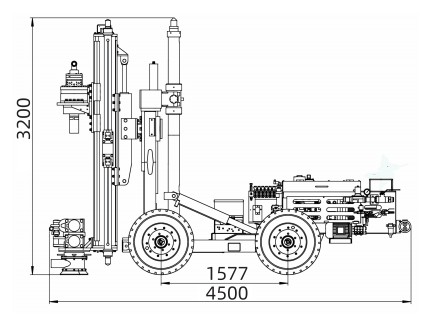

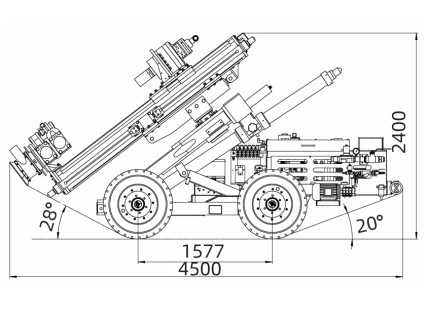

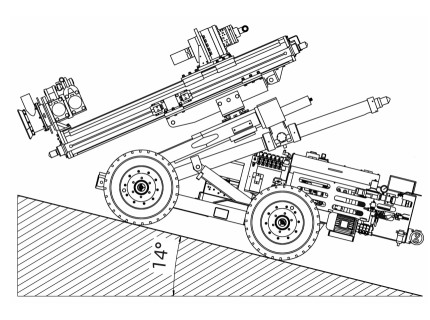

4.Drilling adaptability: The drill rack rotation adopts a gear rack cylinder, with large torque, reliable positioning, and can provide all-round rock drilling. Stable and reliable support mechanism (sub-top, main top, outrigger) ensures drilling accuracy. The optimal applicable stope height is not less than 3.2 m and not higher than 3.6 m, and the tunnel width is not less than 2.6 m.

5.Control performance: The hydraulic disassembly rod system reduces the labor intensity of operators and saves auxiliary operation time. The whole machine realizes long-distance wireless remote control operation, and walking movement, drill arm positioning, and rock drilling operations can all be completed on the remote control. The remote control is equipped with a visual data interface, which can display the single hole depth, cumulative hole depth, drilling angle, etc. in real time.