Product Introduction

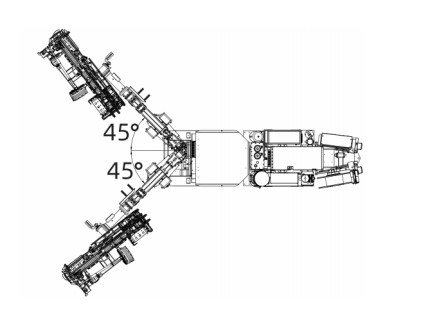

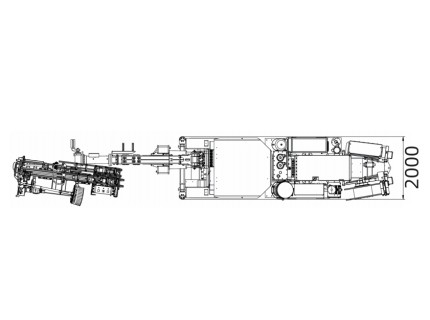

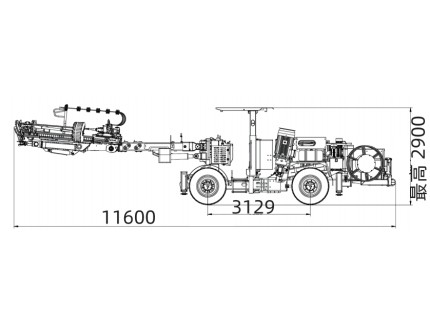

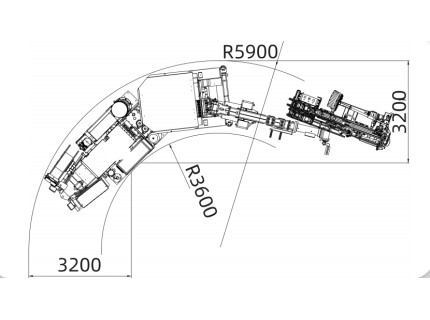

Product Pictures

Product Features

1.Multi-power system: diesel-electric dual power system, diesel power for driving, motor hydraulic drive for each actuator, diesel power can retract each actuator when power is off.

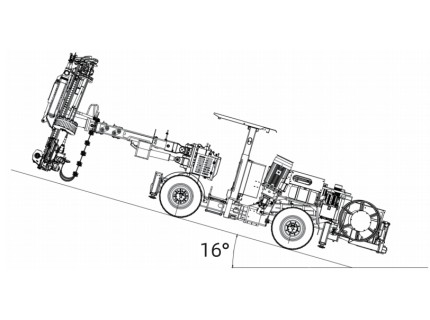

2.Flexibility: The whole machine has a compact structure, multi-gear walking speed is adjustable, four-wheel drive, strong power in small and medium-sized tunnels with various complex working conditions, and flexible driving and turning.

3.Environmental protection: Equipped with hydraulic drill, compared with pneumatic drill, it has lower noice and higher efficiency.

4.High efficiency: Equipped with rod magazine, rods can be automatically replaced; equipped with automatic net hanging mechanism, it can realize mechanized automatic net grabbing, lifting and hanging, and improve the overall support efficiency.

5.Multi-type rod compatibility: Mainly used in common seam pipe types, and other types of rods can be optionally equipped and customized, such as threaded steel (resin) rods, water-rising rods, mechanical rods, etc.

6.Multi-type rock drill applicability: Standard configuration is imported and domestic well-known brands, and other brands of various types of rock drills can be selected according to requirements.

7.Safety: Equipped with safety protection liftable roof, fire extinguishing device, emergency parking brake and other various safety warning systems, it ensures the safety of operation under the premise of achieving the function.

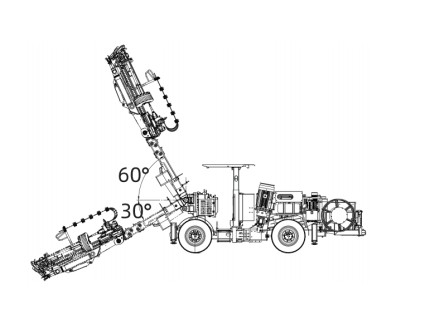

8.Applicability of tunnel range: The propulsion beam rotates 360° and covers the tunnel face in all directions.

9.Maintainability: Open cab, modular component design, reasonable space layout, easy to repair and maintain.

10.Drilling positioning accuracy: Equipped with a stable support mechanism for the drill boom, the rock drill is switched in parallel to ensure the centering of the drilling center and the accuracy of drilling and rod installation.

11.Interchangeability: It has strong universality and interchangeability with the spare parts (hydraulic parts, hoses, joints, lubrication, etc.) of imported well-known brands of rock drills.