Product Introduction

Product Pictures

Product Features

1.Multi-power system: diesel-electric dual power system, diesel power for walking, motor hydraulic drive for each actuator to work, diesel power can retract each actuator when power is off.

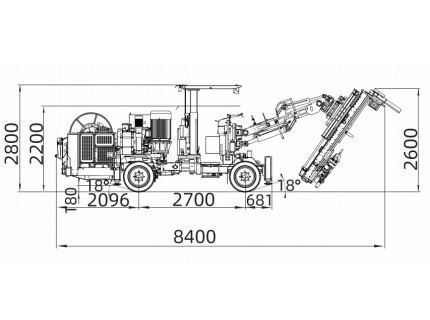

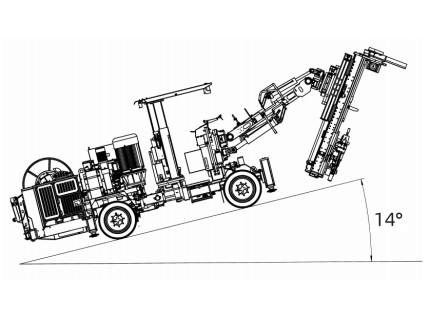

2.Flexibility: The whole machine has a compact structure, multi-gear driving speed is adjustable, four-wheel drive, strong power in small and medium-sized tunnels with various complex working conditions, flexible walking and turning; articulated engineering chassis, detachable, suitable for narrow tunnels, mine tunnels and mines without ramps and other working environments.

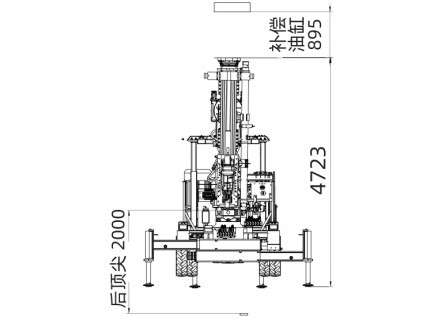

3.Safety: Equipped with safety protection lifting roof, fire extinguishing device, double-bridge wet brake and other various safety warning systems, it ensures the safety of operation under the premise of realizing the function; standard remote control console ensures sufficient safe working distance, easy operation, good vision, and convenient observation of various working conditions such as opening, drilling and connecting drill rods.

4.Interchangeability: It can be used with well-known domestic and foreign brands of rock drills, and has strong universality and interchangeability with the spare parts (hydraulic parts, hoses, joints, lubrication, etc.) of imported well-known brands of rock drills.

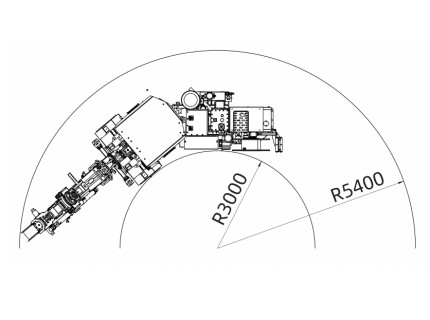

5.Accuracy: Equipped with a stable support mechanism for the drill arm, it is easy and fast to position, accurate and reliable, highly flexible, and can achieve fan-shaped drilling.

6.Open cab, modular component design, reasonable space layout, easy to repair and maintain.

7.Standard remote control console ensures that the operator has enough safe working distance, convenient operation and good vision, and is easy to observe various working conditions such as opening holes, drilling holes, and connecting drill rods.