Product Introduction

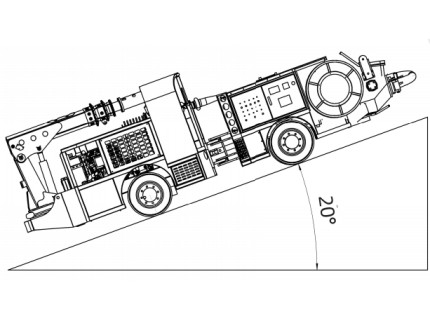

Product Pictures

Product Features

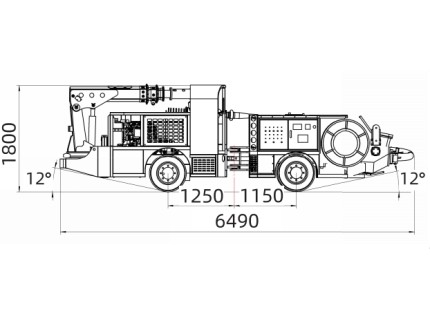

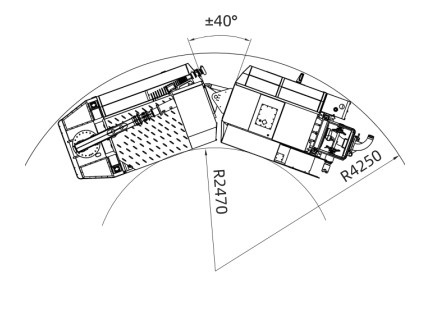

1.The chassis adopts a hydrostatically driven engineering off-road chassis, four-wheel drive, articulated steering, wet brakes, and bidirectional driving.

2.Adopts fully enclosed wet multi-disc spring brake, hydraulic release, fail-safe type brake, meets the safety requirements of mines.

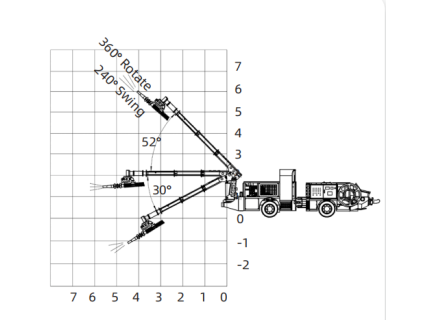

3.The boom is made of high-strength steel plate material, and the fully hydraulic telescopic and rotating mechanical arm has strong load-bearing capacity, stable movement, flexible operation, and no injection blind area.

4.It adopts a German IFM dedicated controller, and the main electrical components are all imported Schneider or Japanese Mitsubishi brands.

5.The hose pump system controlled by imported hydraulic proportional valves is intelligently synchronized according to the preset ratio, the dosage of admixtures and the concrete pumping volume.

6.The air compressor system adopts a large-volume screw air compressor unit. During injection, the air supply of the air compressor can be adjusted steplessly on the remote control according to different injection positions, which can effectively reduce the rebound of the sprayed concrete and improve the surface quality of the sprayed concrete.

7.The wet spraying machine adopts a dual power system configuration. The diesel power can retract and extend the boom and perform emergency pumping and discharging, avoiding accidental power outages or failures that may cause concrete to solidify in the concrete cylinder.