Product Introduction

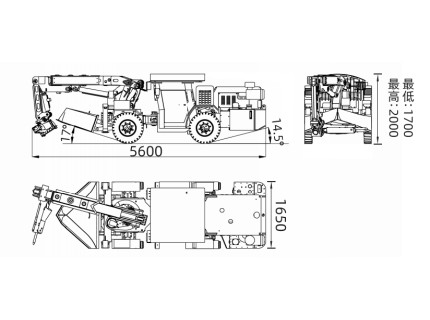

Product Pictures

Product Features

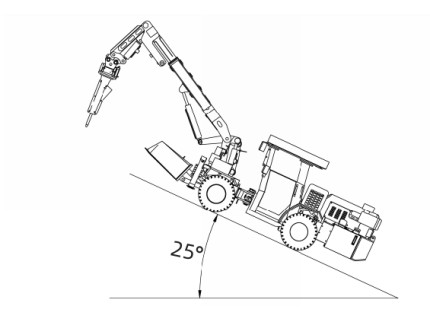

1.Electronic-controlled closed hydrostatic drive engineering chassis, four-wheel drive, large driving torque, high bulldozing ability, and strong climbing performance.

2.The electronic control system collects engine speed and load information, summarizes and processes it, and implements precise control of the displacement of the oil pump, making the chassis more maneuverable and safer, preventing braking and overload from stalling, and effectively protecting the engine and drive system.

3.The cab meets the mine safety ergonomic design, has passed the two international certifications of FOPS anti-falling objects and ROPS anti-rollover, centralized control, reasonable layout, comfortable and convenient; at the same time, the cab can be raised and lowered, pitched, and convenient for personnel to operate accurately.

4.Hydraulic wet dual braking system, driving oil brake, parking closed spring brake, meet the safety use requirements of long ramps and low tunnels in mines.

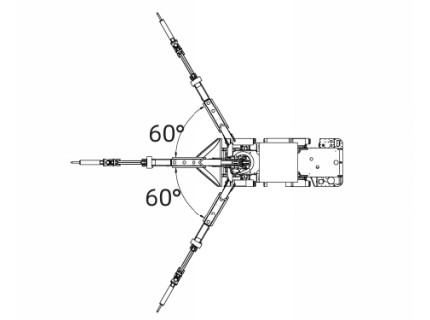

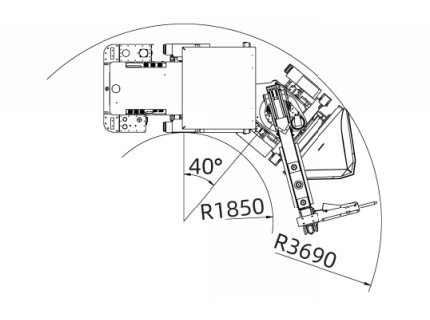

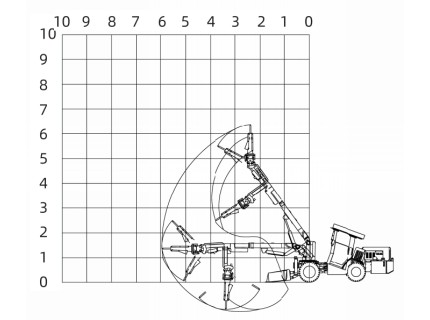

5.The fully hydraulic telescopic and rotating mechanical arm has strong load-bearing capacity, stable movement, flexible operation, and no construction blind spots.

6.The articulated special chassis has a smaller turning radius, which can meet the needs of mine and tunnel operations to the greatest extent.

7.The breaker adopts the Korean engineer brand, with stable performance, flexible steering, high impact energy and small recoil force.

8.The reinforced engineering chassis design enhances the rigidity and strength of the vehicle body, the vehicle weight is larger, and the scaling and crushing stability is better.

9.The boom is equipped with an overload protection system, which can effectively protect the boom and hydraulic cylinder during the contact scaling operation.

10.It is equipped with a slag removal shovel, which can quickly and appropriately clean the blast pile before mucking, so that the scaling rig can go to the working face to clean the loosen stones on the top plate and the side wall, with better passability and stronger adaptability.